“We are set up to be part of the sustainment effort for F-15 aircraft canopies. We are part of the team that does the replacement parts like the canopies, stabilizers or any of the other flight controls that keep F-15 aircraft flying.”-Alberto Garza-Mayer, 572nd Commodities Maintenance Squadron, Robins Air Force Base, Georgia, February 2021

“After a while, flying during storms or other types of weather conditions, the canopy will develop hazing to a point it will not be serviceable anymore and will need to be replaced.”-Alberto Garza-Mayer, 572nd Commodities Maintenance Squadron, Robins AFB, Georgia, February 2021

“The canopies will get disassembled and de-painted. After it is disassembled, we do a frame inspection check to see if the canopy is still serviceable.” -Alberto Garza-Mayer, 572nd Commodities Maintenance Squadron, Robins AFB, Georgia, February 2021

“Once the canopy goes through its necessary repairs, it is resealed where the canopy sits onto the airframe. Then all the holes are located to drill. There are about 3-hundred fastener holes that hold the canopy to the frame. We drill the holes, then trim it to fit within technical order tolerances, make sure it fits, do a final inspection, and install it onto the frame.” -Alberto Garza-Mayer, 572nd Commodities Maintenance Squadron, Robins AFB, Georgia, February 2021

“Last year, we averaged six or seven canopies a month, so we were in the 80-plus canopies completion range. This year, the numbers have been lowered, so we have been doing around four canopies a month.” -Alberto Garza-Mayer, 572nd Commodities Maintenance Squadron, Robins AFB, Georgia, February 2021

At Royal Air Force Lakenheath, England, November 2020, 48th Equipment Maintenance Squadron performed maintenance on a F-15 canopy.

This included buffing-out the canopy.

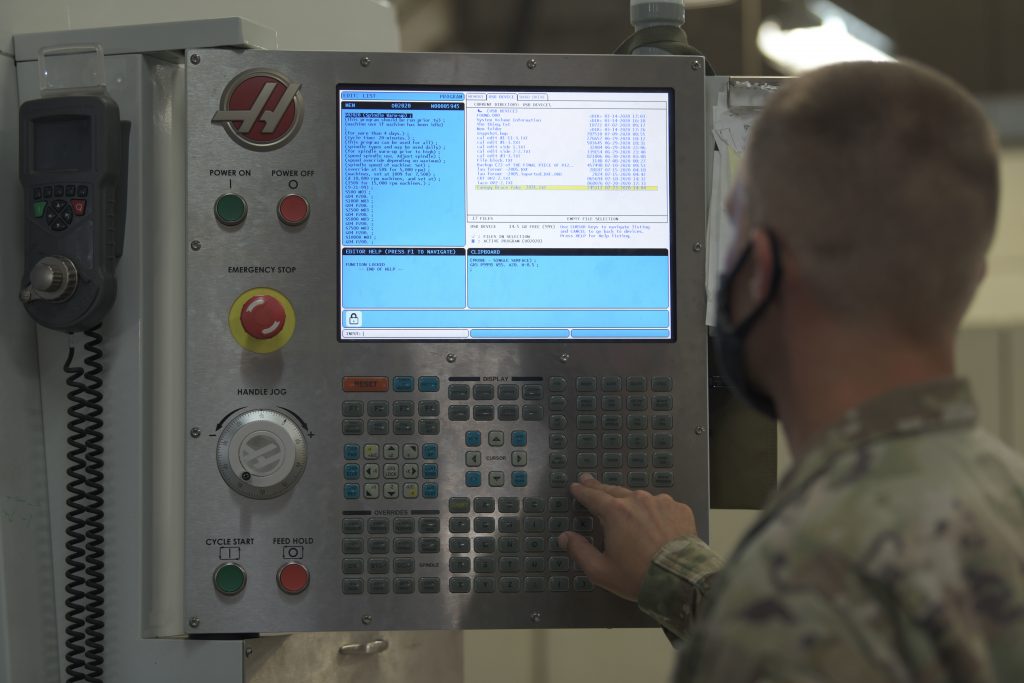

Back in July 2020, 18th Equipment Maintenance Squadron personnel at Kadena Air Base (AB), in Japan, were building their own F-15C canopy braces.

This involved using Computer Numeric Controlled (CNC) program to shape aluminum stock.

The aluminum braces are necessary to prevent warpage of the F-15 canopy.

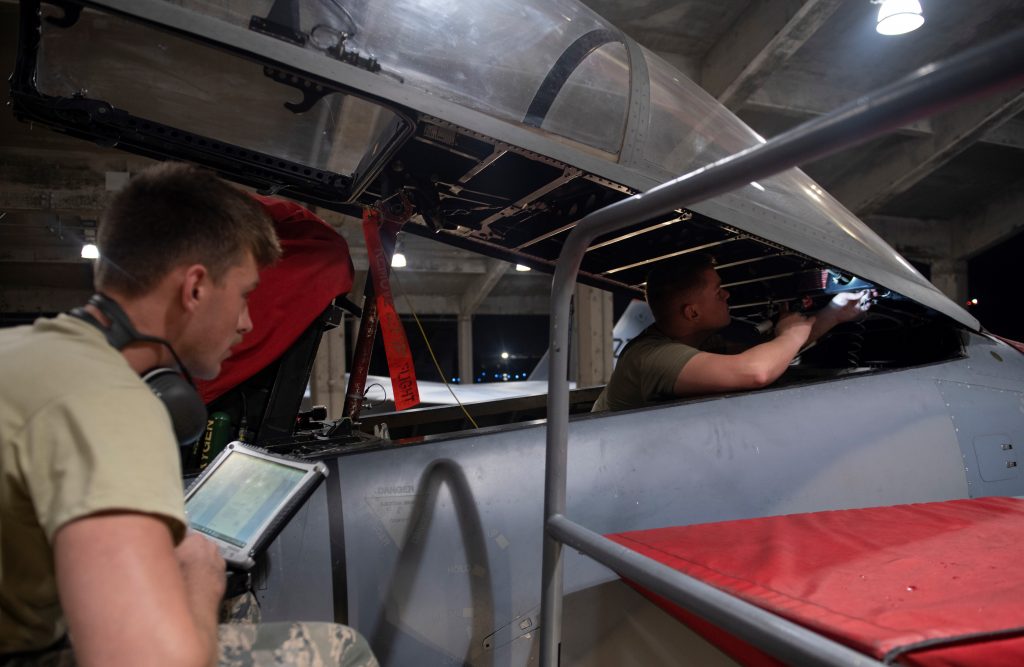

Canopy inspection on F-15C, Kadena AB, September 2019.

What’s left of a F-15 ‘gate guard’ canopy after 2018’s Hurricane Michael hit Tyndall AFB, Florida. (Photo taken in February 2019)

Under the canopy, Kadena AB, October 2018.

An Oregon Air National Guard F-15, from the 173rd Fighter Wing. minus its canopy during phased inspection, October 2014.

Vehicle I-D: IDAHO’S TIGERS & THUNDERBOLTS BLAST THE SKIES OVER FLORIDA!

Vehicle I-D: F-15EX HAS ARRIVED! COMMANDER SAYS “IT’S AN EX-CITING DAY!”

Vehicle I-D: KADENA EAGLE